Using Outside Expertise: A Smart Design Compliance Strategy

Several months ago, the email application (Microsoft Outlook) in my desktop PC suddenly refused to link with the server, and instead returned a numerical error message. I figured, “Hey, I’m an engineer. I should be able to fix this myself.” I searched on the error number and saw it was fairly common. There were sites with, in aggregate, over a dozen suggestions of how to deal with it. Ranging from the obvious (check that the basic settings had not been corrupted), to the arcane (doing a deep dive into the guts of the operating system), to the risky (delete the email account and then re-establish it). I was able to try about half of them and unable to invoke the rest for various reasons. Long story short: I could not fix it, despite my time-consuming efforts.

Finally, after spending 20 to 30 hours on it, I did what was previously unthinkable: I went online and paid for support from a reputable help service. They accessed my PC remotely, and within 20 minutes had solved the problem. By that point, I didn’t want to know what the problem was, just that it was fixed with no additional effort on my end, and for a very modest sum.

That’s when I once again remembered an engineering lesson that hard experience teaches: Don’t hesitate to put your pride aside, when the smartest thing to do is to make use of the expertise of others – and do so even if it means hiring an expert consultant to solve specific problems or, better yet, anticipate and help avoid them in the first place.

Look at the reality of today’s designs: nearly every project or product is not only defined by the marketing requirements but also bounded by numerous regulatory standards. Full compliance cuts across multiple perspectives encompassing performance, safety, and social-policy goals; it includes:

- High-level technical standards: Examples include meeting IEEE 802.x or a medical device performance accreditation.

- Electrical safety standards: These generally increase in severity with the voltage level.

- Medical safety standards: Are primarily related to general electrical standards but are more stringent.

- Mechanical safety standards: Prevent physical harm and access to certain areas.

- Energy efficiency standards: These are getting more stringent and even going so far as to affect smaller products, such as low-power AC-DC adapters.

- EMI and RFI standards: Cover both noise generation and susceptibility.

- Audio standards: Defining how loud the alarms and warnings must be, how quiet the product must be in normal operation, and even the specific alert sounds it must make.

- Reliability assessments and measures for various end applications.

- Defining the various types of written product warning labels and stickers, what they can say, and their size and placement.

- And, of course, the many end-user standards for automotive, mil/aero, and other applications.

Most of these safety standards have the force of law, and products cannot be sold or distributed without compliance. The standards often include details specifying how they are to be evaluated (test instrument, stimulus, and response, data analysis, etc.). Although there has been a trend towards worldwide harmonization of many of these standards, there are also many exceptions and variations between countries or regions. It’s a complicated, multilayered scenario.

Given the many standards which almost every product must meet, and the overlap and even contradictions among many of them, it’s amazing any product actually gets signed off and released to the market. Sometimes, I can’t but compare the situation of today’s engineer as being in a position analogous to the title character in Jonathan Swift’s classic work, “Gulliver’s Travels.” In the Lilliputian segment, he is a striding giant among tiny creatures and is not concerned about them, until they start tying him down with countless threads while he is sleeping and is soon immobilized (Figure 1). (This is sometimes called “Death by a thousand cuts” or getting “Nickeled and dimed to death.”)

Figure 1: Like Gulliver and the Lilliputians (as seen in this 1726 illustration), today’s designer is often expected to create great products while being constrained by innumerable large and small standards for mandated compliance. (Image source: Fine Art America/Mary Evans Picture Library)

Figure 1: Like Gulliver and the Lilliputians (as seen in this 1726 illustration), today’s designer is often expected to create great products while being constrained by innumerable large and small standards for mandated compliance. (Image source: Fine Art America/Mary Evans Picture Library)

Start with power supplies

Vendor sites for insight on component issues are a good starting point, as these suppliers usually have studied the regulatory standards carefully and have even had input on their creation. The posted material can range from smaller topics such as the difference between common terms such as “UL Listed” versus “UL Recognized” (Figure 2).

Figure 2: There are many subtleties in regulations and designations, including the difference in meaning and logo for “UL Listed” versus “UL Recognized.” (Image source: Triad Magnetics)

Figure 2: There are many subtleties in regulations and designations, including the difference in meaning and logo for “UL Listed” versus “UL Recognized.” (Image source: Triad Magnetics)

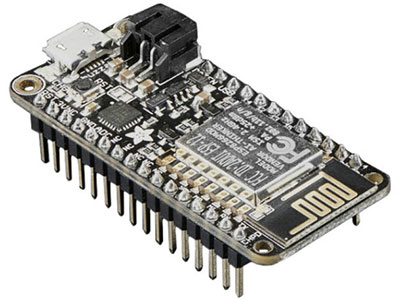

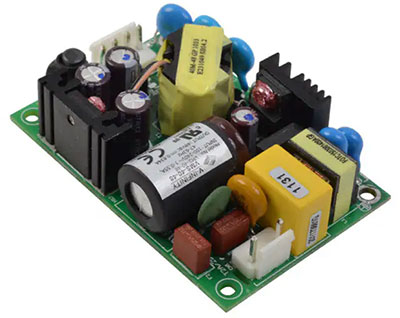

A good place to begin is with the AC-DC power supply. For instance, a supply such as CUI Inc.’s VOF-50-15, a 15 volt/50 watt unit meets a wide range of applicable standards (Figure 3). These standards include IEC 60950 (safety); EN 55022; EN 61000; and others (EMI/EMC). It is characterized by mean time between failure (MTBF), per MIL-HDBK-217F.

Figure 3: The VOF-50-15 AC-DC supply (15 volt/50 watts) meets all relevant international standards covering basic safety, EMI/EMC, and MTBF assessment. (Image source: CUI Inc.)

Figure 3: The VOF-50-15 AC-DC supply (15 volt/50 watts) meets all relevant international standards covering basic safety, EMI/EMC, and MTBF assessment. (Image source: CUI Inc.)

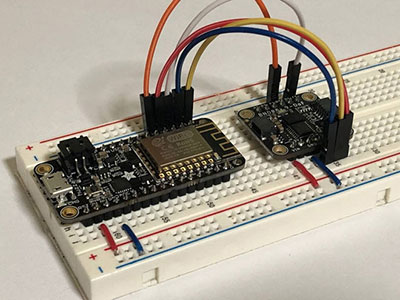

Despite its many certifications, this supply is not acceptable for medical applications as they require additional insulation and extremely low leakage current per IEC 60601-1-11:2015. A more appropriate choice would be a power supply in the CUI VMS-40 series such as the VMS-40-24 (24 volts, 40 watts) which also meets the IEC medical standard (Figure 4).

Figure 4: In addition to meeting the relevant international standards covering basic safety, EMI/EMC, and MTBF, the VMS-40-24 (24 volts, 40 watts) AC-DC supply meets the IEC 60601-1-11:2015 standard for medical power supplies. (Image source: CUI Inc.)

Figure 4: In addition to meeting the relevant international standards covering basic safety, EMI/EMC, and MTBF, the VMS-40-24 (24 volts, 40 watts) AC-DC supply meets the IEC 60601-1-11:2015 standard for medical power supplies. (Image source: CUI Inc.)

If AC-DC supply certification were the only compliance concern affecting a product and final approval, the design could simply move ahead. However, while the use of approved or compliant components is important, that does not ensure that the overall design will pass. For example, there are minimum component and board creep/clearance dimensions unrelated to the supply compliance. Many other standards also apply simultaneously.

Determining which ones do apply—and to what extent—is a challenge in itself. A compliance expert can help navigate the regulatory maze, make those determinations, prioritize among them, and manage their unavoidable overlap and contradictions. The right expert (or specialist) can help identify potential problem areas before they are set into the design, whether they are tangible ones, such as creep and clearance distances, or elusive ones, such as minimizing RFI/EMI emissions. In the latter case, the expert can guide the hands-on effort of finding the problem, proposing solutions, and weighing the tradeoffs among approaches, which may include shielding, ferrite beads, bypassing, and more.

Conclusion

Vendor blogs and application notes are an important first step to understanding the intricacies and context of the multiple technical standards and regulatory mandates impacting every design. However, the multifaceted issues related to compliance are complicated and intertwined. If in-house resources are not available, calling on experienced outside consultants early in the design cycle can minimize compliance-related project problems.

Recommended Reading:

“CUI IEC 62368-1 compliant power supplies”

https://www.digikey.com/en/product-highlight/c/cui/iec-62368-1-certified-power-adapter

“IEC 62368-1 Is on Its Way: The New Safety Standard for ICT and AV Equipment”

“Medical Power Supplies and the IEC 60601-1 Medical Design Standards”

“PUI Audio Speakers & IEC 60601-1-8: How to Choose the Right Speaker”

https://www.digikey.com/en/pdf/p/pui-audio/pui-audio-speakers-and-iec-60601-1-8

“How to Properly Implement Audible Alarms in Medical Monitoring”

https://www.digikey.com/en/articles/how-to-properly-implement-audible-alarms-in-medical-monitoring

“Circuit Protection Product Overview”

https://www.digikey.com/en/ptm/l/littelfuse-inc/circuit-protection-product-overview/tutorial

“Quiet, Please! Go Ahead and Add Your Alerts, But Only Those That Are Really Needed”

https://www.digikey.com/en/blog/quiet-please-go-ahead-and-add-your-alerts

“Medical Supply Safety: The Ultimate AC/DC Challenge?”

https://www.digikey.com/en/blog/medical-supply-safety-the-ultimate-ac-dc-challenge

“How to Select and Apply the Right Components to Protect Medical Devices, Users, and Patients”

https://www.digikey.com/en/articles/how-to-select-and-apply-the-right-components-to-protect-medical

“The Right Power Supply is Critical to Meet the New IEC/UL IEC-62368 Consumer Product Safety Mandate”

External References

1 – Triad Magnetics. “UL Listed versus UL Recognized”

https://info.triadmagnetics.com/blog/ul-listed-vs-ul-recognized

2 – CUI Inc., “IEC 60601-1-2 4th Edition: What You Need to Know”

https://www.cui.com/blog/medical-60601-1-4th-edition

3 – CUI Inc., “IEC 60601-1 Medical Design Standards for Power Supplies”

https://www.cui.com/catalog/resource/2480

4 – CUI Inc., “Be Prepared for the 4th Edition of the IEC 60601-1 Medical Standard”

5 – Minntronix, “Calculating Creepage and Clearance Early Avoids Design Problems Later”

https://www.minntronix.com/application/files/2914/5948/1301/CreepageandClearance.pdf

6 – Tempo Automation, “Understanding PCB Creepage and Clearance Standards”

https://www.tempoautomation.com/blog/understanding-pcb-creepage-and-clearance-standards/

Have questions or comments? Continue the conversation on TechForum, DigiKey's online community and technical resource.

Visit TechForum